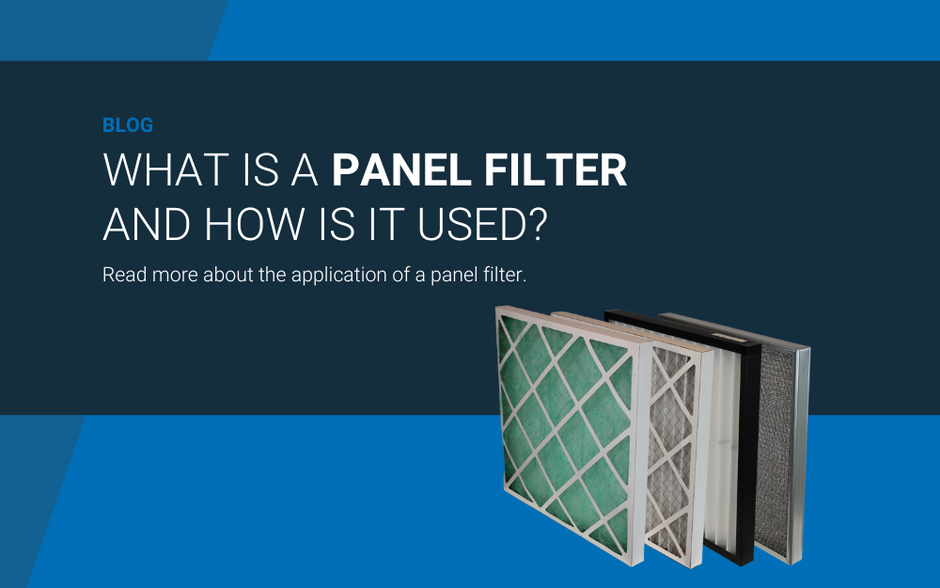

Panel filters are used in ventilation systems and air handling units. They help ensure clean and healthy air in both residential and workplace environments. In this blog, Ilja will tell you more about what panel filters are, how they are used, the benefits they provide, and the different types of panel filters available.

What is a panel filter?

A panel filter is an air filter used to remove particles such as dust, pollen, dirt, and other contaminants from the air. Panel filters have a flat, rectangular, or square shape and consist of a frame containing the filter medium. The filter medium is made from materials such as synthetic fibers, fiberglass, or activated carbon, depending on the application.

How do panel filters work?

The filter medium in a panel filter captures contaminants as air flows through it. This process not only helps purify the air but also ensures the efficiency of the ventilation system. Panel filters are typically used as pre-filters in an air handling unit, followed by other filters. This means they are deployed in the first stage of air filtration to filter out larger particles from the air. Thanks to this first filtration stage, subsequent filters, such as fine dust filters or activated carbon filters, can operate more efficiently and last longer.

Regular replacement of panel filters is essential to maintain optimal airflow and guarantee the system's effectiveness. Timely replacement ensures good airflow, which leads to stable operation of the air handling unit and a longer lifespan for any subsequent filters.

How is a panel filter used?

Panel filters are primarily applied in HVAC systems (Heating, Ventilation, and Air Conditioning) and industrial installations where it is important to maintain clean air.

The most common applications for panel filters are:

- Ventilation systems in buildings: In homes, offices, and industrial environments, panel filters are used to improve air quality by filtering out contaminants.

- Industrial installations: In factories and workshops, panel filters are used to remove airborne contaminants such as dust, smoke, and fumes, which is important for both worker health and the reliability of equipment.

- Healthcare: In hospitals, laboratories, and pharmaceutical environments, panel filters ensure that the air is as free from contaminants as possible, which is essential for creating and maintaining a healthy environment. Panel filters also extend the lifespan of absolute filters by providing pre-filtration.

- Food production: In the food industry, panel filters are used to minimize the impact of air contaminants on the quality of food products.

Why are panel filters important?

A well-functioning panel filter not only provides cleaner air but also offers other benefits such as:

- Improved air quality: Panel filters remove contaminants such as dust, pollen, and bacteria from the air, resulting in a healthier living and working environment.

- Protection of equipment: By filtering dust and dirt from the air, panel filters extend the lifespan of ventilation and HVAC systems and reduce the need for regular maintenance.

- Energy efficiency: A well-maintained panel filter ensures better airflow, which increases the efficiency of air handling systems and helps reduce energy costs.

- Versatility: Panel filters are available in different types and sizes, allowing them to be used in a variety of environments and applications.

Different types of panel filters

There are various types of panel filters designed for specific applications. Below is an overview of the most common types:

Wire frame filters

Wire frame filters have a simple frame made of wire. They are lightweight and are often used to capture coarse dust particles. These filters are used to protect fan-coil units, air heaters, or heat recovery units.

Metal filters

Metal filters are made from a fully metal construction, usually of aluminum or stainless steel. They have a robust metal construction and can generally be washed and reused.

Panel filters AL2

Panel filters AL2 are square or rectangular filters consisting of a metal profile with an open metal mesh on both the front and back, with a synthetic filter mat or PPI filter material in between. These filters are often used in commercial HVAC systems due to their long lifespan and reliability.

Panel filters cardboard frame interpleat

These filters have a cardboard frame and a sturdy pleated filter medium. They are easy to install and replace and have a long lifespan. They are used as (pre)filtration in air handling units or air intake grilles.

![]()

Panel filters plastic frame FZK

Panel filters with a plastic frame have a large filter surface area for a long lifespan. They are moisture-resistant and mechanically very strong. These filters are used for medium-class filtration in air handling units or air intake grilles.

Panel filters metal frame FZG

The FZG panel filters have a sturdy metal frame, typically made of aluminum or galvanized steel, making them robust and suitable for harsh conditions. These filters are commonly used in industrial environments where durability and long lifespan are essential.

Panel filters minipleat FZMP

Minipleat filters have a densely pleated design, which provides a larger filter surface area within a compact frame. This type of filter offers very high efficiency in removing small particles such as fine dust and bacteria. FZMP filters are used for medium filtration in air handling units with a pre-filter.

Panel filters with carbon

Panel filters with carbon in the medium are used for (pre)filtration in air handling units or air intake grilles. The difference from regular interpleat filters is that these panel filters are designed to capture unwanted odors and/or gases.

Glass panel filters

Glass panel filters are used for coarse (pre)filtration in air handling units or air intake grilles. These filters are 100% combustible, have a high dust holding capacity, and offer good energy consumption due to their low resistance.

Free advice

If you have questions about which type of panel filter best suits your situation or would like more information after reading this blog, our experts are ready to help! Feel free to contact us for personalized advice.

You can reach us via email at info@interfilter.nl, or you can directly chat with one of our advisors.

EN

EN

NL

NL PL

PL