Efficiency, Reliability, and Durability with Transair

In modern industry, efficiency and reliability are crucial for the success of any business. One of the essential aspects of industrial processes is transporting air, gas, and liquids. This is where the Transair piping system comes into play, a revolutionary solution that raises the standards for the design, installation, and performance of piping systems. In this blog, I will take you through the world of Transair piping and explore why it is such a valuable asset for today's industrial applications.

What is Transair piping?

As a Parker distributor, we also supply complete piping systems from the Transair brand. Transair is an advanced modular piping system developed by the internationally renowned company Parker Hannifin. This system offers a reliable, efficient, and cost-effective way to transport air, gas, and liquids in industrial applications, including manufacturing, automation, pharmaceuticals, and more.

View the Transair piping system product page

What are the benefits of Transair pipes?

Choosing the Transair piping system comes with various advantages.

Fast and Easy Installation

The Transair piping system uses quick-connect technology and aluminum pipes that can be assembled without welding. This means installation is much faster and easier compared to traditional piping systems. The modular design allows for modifications and expansions at any time, saving both time and costs.

High Reliability and Leak-tightness

The Transair piping system uses a unique "push-to-fit" coupling system that ensures a leak-tight connection. This significantly reduces the risk of leaks, which is critical for processes requiring a high level of reliability. In addition, all Transair pipes are PED certified from the factory.

Weight Saving

The use of aluminum pipes instead of traditional steel pipes results in significant weight savings. This is particularly valuable for applications where weight control is important, such as the load-bearing capacity of a roof structure.

Durability and Corrosion Resistance

Aluminum is naturally resistant to corrosion, which enhances the durability and lifespan of the Transair piping system. This reduces maintenance costs and significantly extends the system's service life.

Energy Efficiency

The Transair piping system is designed to ensure efficient airflow, minimizing energy loss. This helps businesses reduce energy costs and lower their environmental footprint.

Flexibility and Modularity

The modular design of Transair piping offers maximum flexibility. The system can be easily adapted to changing needs and can be dismantled and reinstalled at another location, making it a cost-effective long-term investment.

Transair Aluminum or Stainless Steel Series

There are two different series of piping within Transair. You can choose between the aluminum piping or the stainless steel variant.

Transair Aluminum Series

The Transair Aluminum Series is the flagship of Transair piping. Made from high-quality aluminum, this system offers a unique combination of lightweight, efficiency, and easy installation. The aluminum piping is easy to handle and assemble, reducing installation time and increasing productivity.

Key Features of Aluminum Pipes

- Lightweight: Aluminum pipes are much lighter than traditional steel pipes, making them easy to handle and install.

- Efficiency: The smooth inner wall of aluminum pipes minimizes pressure loss, ensuring efficient airflow.

- Easy Installation: The push-to-fit coupling system allows for quick and leak-free connections without the need for special tools or welding.

Applications of the Transair Aluminum Series

The aluminum series is ideal for compressed air applications in various industries, including manufacturing, automation, and automotive. It is also widely used in workshops, laboratories, and other environments where efficient and reliable compressed air is needed.

Transair Stainless Steel Series

For industrial environments where corrosion resistance and durability are crucial, the Transair Stainless Steel Series provides the perfect solution. Made from high-quality stainless steel, this system offers the same efficiency and reliability as the aluminum series, but with extra resistance to corrosive substances.

Key Features of Stainless Steel Pipes

- Corrosion Resistance: Stainless steel pipes are resistant to corrosion and rust, making them suitable for demanding environments.

- Durability: Stainless steel pipes have a long lifespan and maintain their performance in harsh conditions.

- Smooth Inner Wall: Like the aluminum series, the stainless steel series has a smooth inner wall to minimize pressure loss.

Applications of the Transair Stainless Steel Series

The stainless steel series is widely used in industries such as chemicals, food processing, pharmaceuticals, and other environments where corrosive substances are present.

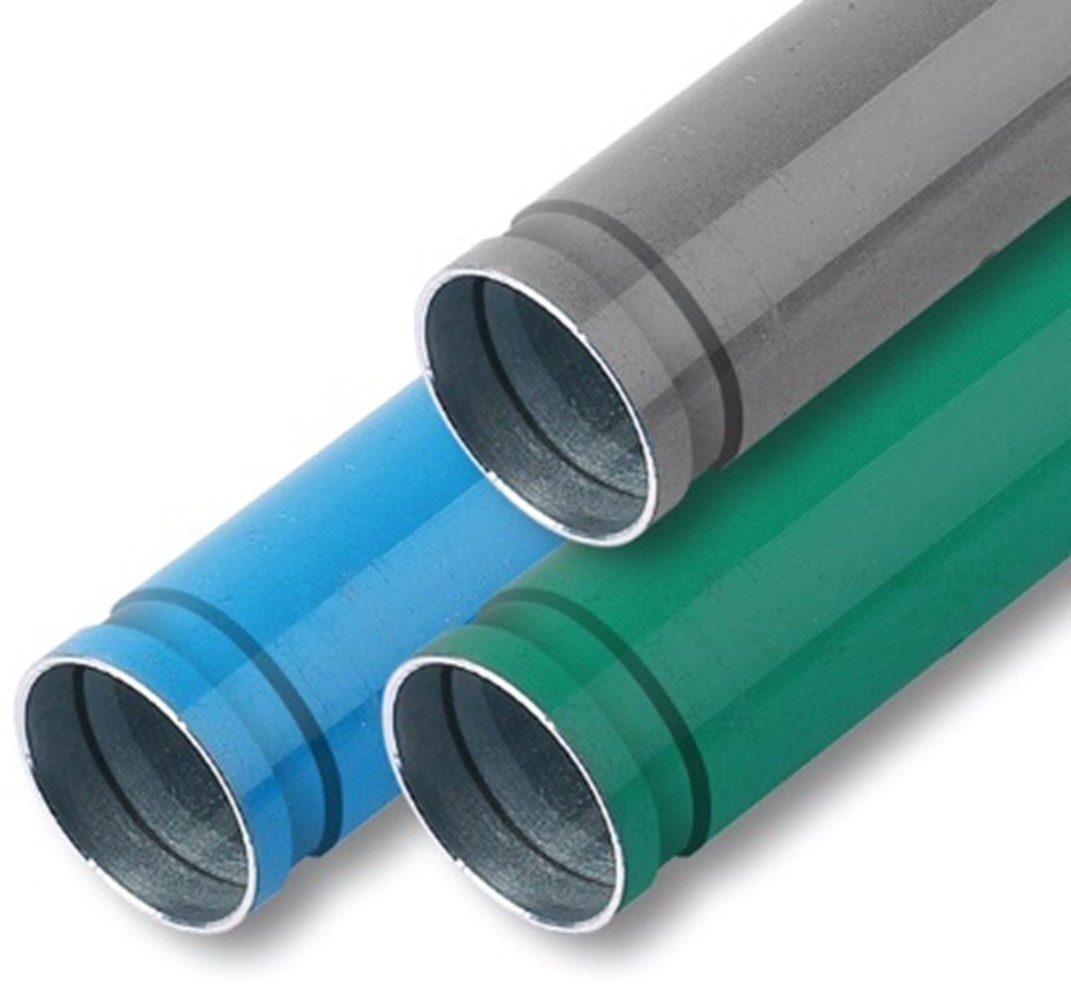

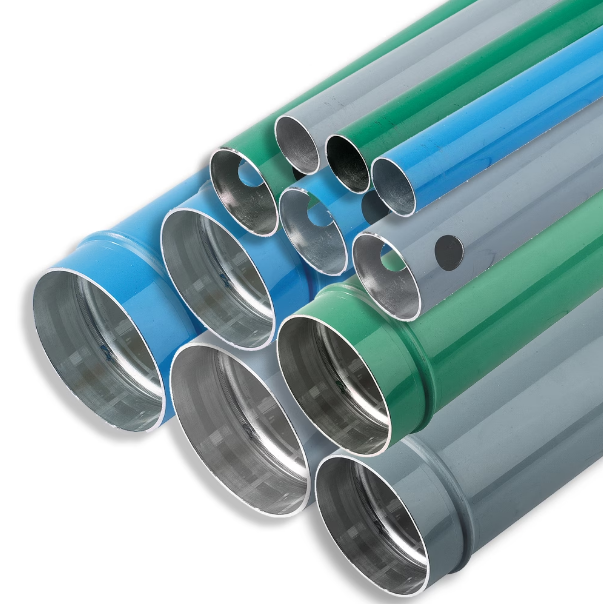

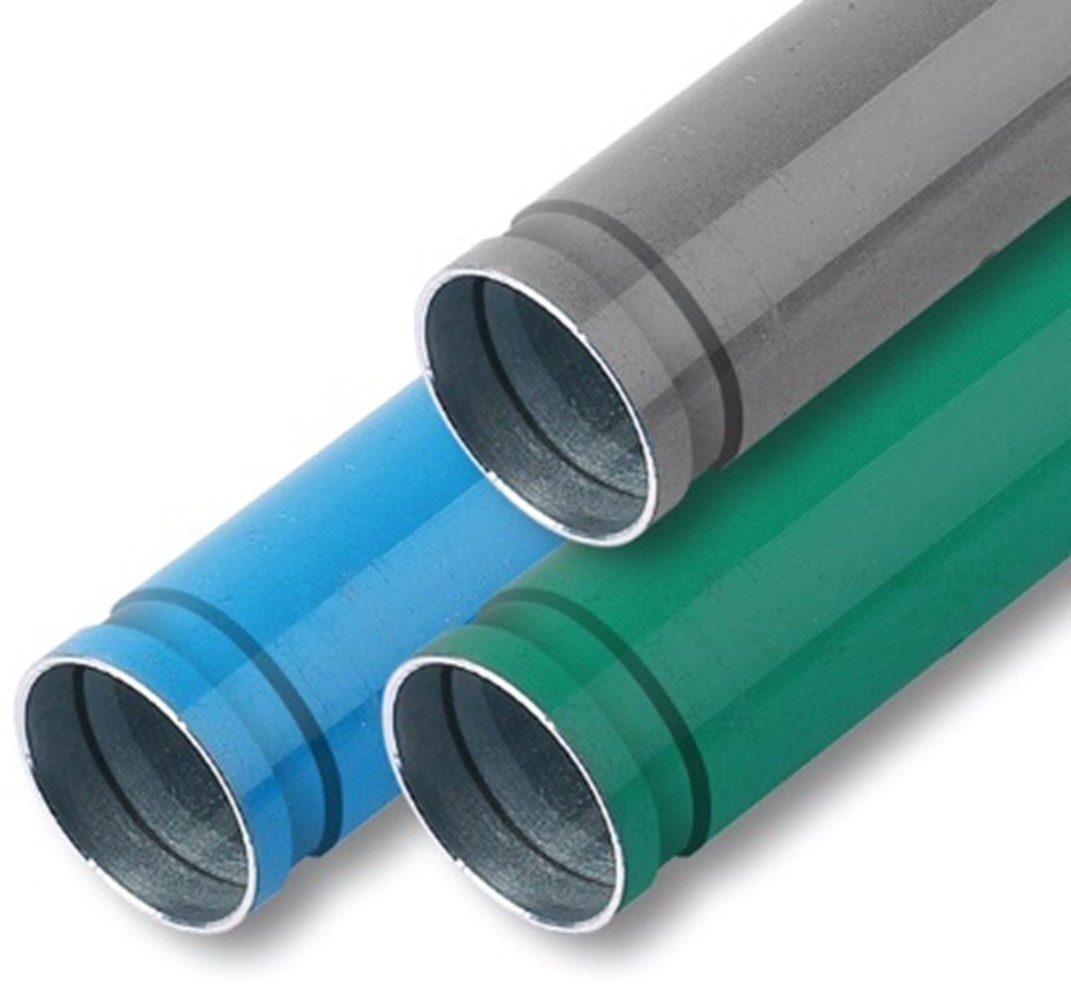

The Different Colors of Transair Pipes

What makes Transair even more unique is the use of different colors for the piping systems. The colors of Transair piping not only provide an aesthetically pleasing appearance but are also a valuable tool for quickly identifying the right pipes for specific applications.

Blue Compressed Air Pipes

Blue is synonymous with compressed air piping within the Transair system. Compressed air piping is a widely used medium in countless industrial applications, from manufacturing to automation. The blue compressed air piping system from Transair offers reliable, leak-tight connections that are essential for efficient airflow. Whether driving machines, tools, or pneumatic applications, the blue compressed air pipes ensure optimal air supply, minimize pressure loss, and support your productivity.

Green Nitrogen Pipes

Nitrogen is an essential gas in various industrial processes, from food packaging to pharmaceutical production. Transair uses the color green to represent nitrogen applications. The green gas pipes from Transair are designed to safely and efficiently transport nitrogen gas. Whether for nitrogen storage, inertization, or use as a cooling or preservation agent, the green nitrogen piping system provides a high-quality solution to optimize your nitrogen processes and lower production costs.

Gray Vacuum Pipes

Vacuum applications are essential in many industries, such as packaging, chemicals, and pharmaceuticals. Transair uses the color gray to mark vacuum applications. The gray pipes from Transair are perfectly designed to manage vacuum processes and exhaust gas extraction. The gray piping system provides leak-tight connections and ensures a clean and safe working environment.

Transair Couplings

Transair piping uses quick-connect technology, where aluminum pipes can be assembled without welding using Transair couplings. This means the installation is much faster and easier than traditional piping systems. The modular design of the Transair couplings allows for adjustments and expansions of the compressed air piping system at any time, saving both time and costs.

Applications of Transair Piping

The Transair piping system is used in various industrial applications, including:

- Compressed air applications

- Cooling water circuits

- Vacuum applications

- Gases (nitrogen, oxygen, argon, etc.)

- Chemical transfer

- Water and wastewater treatment

Energy Monitoring System

We also offer advanced sensors for energy management and monitoring in industrial piping systems. This system is equipped with integrated sensors that perform pressure measurements, giving you in-depth insight into your compressed air network. This allows you to accurately monitor energy consumption and any leaks in the system. With sensors in your piping system, you can achieve energy savings, optimize the efficiency of your compressed air system, and lower your business costs.

So Why Transair

Transair piping is a groundbreaking solution that has transformed the way industrial piping systems are designed, installed, and used. With its fast installation, reliability, durability, and energy efficiency, the Transair piping system has proven itself as a valuable asset for a wide range of industrial applications. Companies switching to this advanced system can not only benefit from higher performance and cost-effectiveness but also strengthen their commitment to sustainability and environmental conservation. In short, Transair piping is a step forward in the evolution of industrial piping systems and is expected to continue playing a central role in the industry of the future.

Installing the Transair Piping System

We also offer the option to install or replace your complete piping system.

Free advice on Transair Piping?

Would you like to learn more about Transair piping and how it can optimize your industrial processes? Feel free to contact me for a detailed and non-binding consultation at ivar@interfilter.nl

Interested in requesting a quote directly? Please call the general number +31 (0)181 32 08 88 or fill out the contact form, and we will respond during office hours within 4 hours.

EN

EN

NL

NL PL

PL