Healthy air quality is essential for our health and the environment. Unfortunately, air pollution and particulate matter in both urban and rural areas pose a growing challenge. One of the most effective solutions to improve indoor air quality is the use of high-quality bag filters in ventilation and air treatment systems. In this blog, you will discover how bag filters contribute to cleaner air and a better living environment.

The impact of air quality on health and the environment

Air pollution is caused by sources such as traffic, industry, construction projects, and natural phenomena like wildfires. These sources release harmful substances into the air, including particulate matter, nitrogen dioxide, and volatile organic compounds. This leads to:

- Health problems, such as respiratory issues, asthma, and cardiovascular diseases.

- Environmental damage, such as soil and water acidification and loss of biodiversity.

- Climate change, exacerbated by greenhouse gases that further degrade air quality.

Improving air quality is crucial to counter these negative effects and create a healthy living environment.

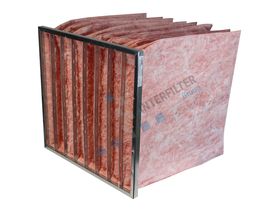

Why choose bag filters?

Bag filters are specifically designed to effectively remove pollutants from the air. They are widely used in both ventilation systems and industrial air handling installations, thanks to their high efficiency and long lifespan. These filters capture airborne particles, including harmful particulate matter, and with a carbon layer, also gases and odors.

Key features of bag filters:

- High filtration capacity: Removes particles as small as 0.3 microns, including fine dust harmful to health.

- Long lifespan: Due to a large filter surface and smart construction, bag filters are durable.

- Flexibility: Available in various sizes and efficiency classes, suitable for a wide range of applications.

- Energy efficiency: With low pressure drop, bag filters consume less energy compared to panel filters, reducing costs and environmental impact.

How do bag filters contribute to healthy air quality?

Bag filters capture harmful substances before they enter a building via the ventilation system. This results in a healthier indoor climate, especially in urban areas with polluted outdoor air.

Bag filters improve air quality by:

- Capturing fine particles (PM1, PM2.5, and PM10): This prevents harmful particles from reaching deep into the lungs.

- Reducing gaseous pollutants: Filters with activated carbon remove odors and volatile organic compounds.

Where are bag filters used?

Bag filters are a popular solution for improving air quality in various applications, including:

- Commercial buildings: Offices, shops, and hotels benefit from clean air for a pleasant working environment and customer experience.

- Industrial environments: Bag filters capture harmful particles and chemicals, making the workplace safer and minimizing emissions.

- Healthcare: In hospitals and clinics, bag filters ensure sterile air supply for patients and staff.

Bag filters provide a proven effective solution to improve air quality. With an optimal filtration system equipped with bag filters, you can reduce health risks, save costs, and contribute to a more sustainable future.

Various types of bag filters

Interfilter supplies bag filters in various types, sizes, and designs tailored to your specific needs. Our range includes both synthetic and fiberglass bag filters. The main difference lies in the material of the filter fabric and its construction. The choice of material and fabric structure plays an important role in the effectiveness and lifespan of the filter in your situation.

Our filter bags are standardly delivered with a steel frame for precise dimensions and optimal strength. If desired, the filters can be equipped with a plastic or wooden frame. This ensures you always have a bag filter that perfectly fits your installation and application.

Lean Filter with Circular frame

The most recent development in bag filters includes filters with a reusable aluminum frame. The frame can be reused repeatedly, and only the contaminated filter bags are disposed of in this concept. These bag filters are the most sustainable and are available in various sizes and filter classes.

Filter classes of bag filters

Bag filters are classified into specific filter classes according to the international ISO 16890 standard. This standard allows you to always select the right filter for your specific application. Below is an overview of the filter classes:

- ISO ePM1: These filters capture at least 50% of all fine particles of 1 micron and smaller. They are ideal for applications in polluted outdoor air environments requiring high indoor air quality, such as healthcare facilities, offices, schools, and laboratories.

- ISO ePM2.5: These filters capture at least 50% of all fine particles of 2.5 microns and smaller. Ideal for urban environments where air pollution is a concern but less stringent air quality requirements apply compared to situations needing ePM1 filters. This filter class is also used for return filters and pre-filters.

- ISO ePM10: These filters capture at least 50% of all fine particles of 10 microns and smaller. They are suitable for urban environments where air pollution is a concern but with less stringent air quality requirements than those for ePM2.5 filters. This filter class is also used for return filters and pre-filters.

- ISO Coarse: These filters capture less than 50% of particles 10 microns or smaller. These are coarse filters used as pre-filters, return filters, or where indoor air quality requirements are minimal.

Eurovent-certified bag filters

Most of our air filter range is Eurovent certified. Eurovent-certified bag filters meet the highest standards for efficiency and performance. Eurovent certification guarantees reliable performance, energy efficiency, and durability, contributing to a clean and healthy indoor climate.

Custom bag filters

In addition to standard-size bag filters, we also supply non-standard size bag filters, which we can produce in-house to almost any desired dimension. Our efficient processes and modern production facilities enable us to deliver the highest quality according to your specifications. This means you don’t have to wait long for custom solutions from external suppliers and can always rely on fast, reliable service.

How to select the right bag filter?

As discussed in this blog, bag filters have many different features, such as the medium, frame, filter class, dimensions, Eurovent certification, and more. Choosing the right bag filter depends on several factors, such as the application, air quality requirements, and ventilation system characteristics. Here are some key considerations:

- Filter class: Determine the required filtration level based on the ISO 16890 standard. For example, an ePM1 filter is suitable for environments with high concentrations of fine dust, while an ePM10 filter suffices for less stringent requirements.

- Application area: Consider the specific requirements of the environment, such as odor removal in kitchens or capturing harmful chemicals in industrial settings.

- Airflow and pressure drop: Choose a bag filter that matches the airflow and generates minimal pressure drop to maximize energy efficiency.

- Material choice: Select between synthetic or fiberglass bag filters based on durability and filtration requirements. Filters with a carbon layer or a circular frame may be the best option for special applications.

- Dimensions and compatibility: Ensure the filter fits the technical specifications of your air handling system to avoid leaks and reduced performance.

Additionally, we consider reducing waste, lowering energy consumption, and extending filter lifespan by incorporating higher dust-holding capacities when selecting the right filter.

Free advice on bag filters

Curious how bag filters can improve air quality in your situation? Or want to ensure you select the most optimal filter? Contact us for free advice and discover which filtration solution best fits your needs. Together, we can create a cleaner and healthier future.

EN

EN

NL

NL PL

PL