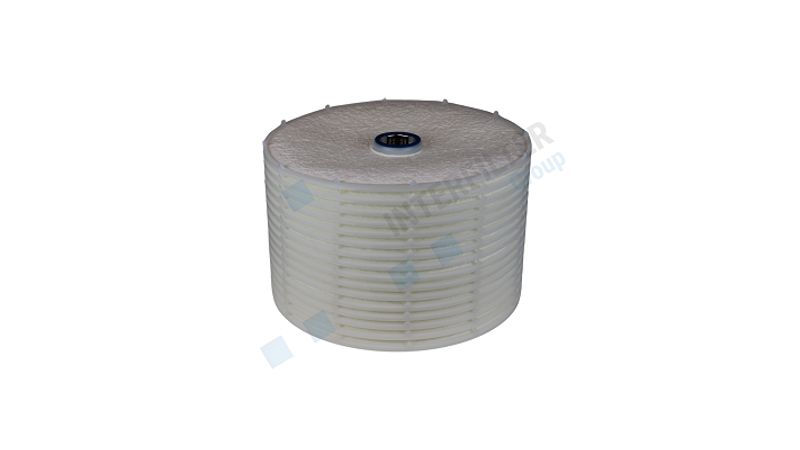

Lenticular filters

Efficient purification of liquids

Part description

Lenticular filters are compact and modular filters suitable for efficiently purifying liquids in various industries. Their disc-shaped design provides a large filtration surface, allowing them to effectively remove solid particles and impurities. These filters use adsorption to bind impurities to their surface, contributing to more thorough filtration.

Additionally, lenticular filters are easy to install and replace, and their closed system minimizes the risk of contamination. This makes them ideal for environments where high hygienic standards are required.

Specifications and Options

- Media: Cellulose fibers with inorganic filter aids and resin binders; cellulose, binder resin, diatomaceous earth and/or carbon

- Media Support: USP Class VI Polypropylene

- Flat Adapter: Polypropylene

- Casing Bands: Stainless Steel

- Film: Double layer USP Class VI Polyethylene EVOH/Nylon

- O-rings/Seals: EPR, Silicone, Nitrile, Viton®, Teflon®, Expanded Teflon®

- Bayonet Adapter: Polypropylene with stainless steel ring

- Hose: Reinforced USP Class VI Silicone

- Fittings: USP Class VI Polypropylene

- Support Material: Polypropylene

- Autoclave: 30 minutes at 121°C (249°F)

- In-situ Steam: 20 minutes at 134°C (273°F), 1 hour at 126°C (258°F)

- Maximum Pressure: 35 psid @ 60˚C

- Maximum Temperature: 32 < > 82˚C

- Recommended Flow Rate: 0.26 < > 1 gpm/ft², 20 < > 40 L/min/m²

- Recommended Pre-Use Rinse Volume: 5 liters/ft² clean water or product

- Cartridge Size Diameter (cm): 28.5 < > 42.6

Applications of Lenticular Filters

Lenticular filters are versatile filtration systems used in industries such as food and beverage, chemicals, and pharmaceuticals. For example, they clarify beers, wines, and juices by removing impurities. In the chemical industry, they handle aggressive liquids, while in pharmaceuticals, they contribute to the purification of proteins and vaccines. Thanks to their compactness and high flow rate, they are an efficient choice for various applications.

EN

EN

NL

NL PL

PL