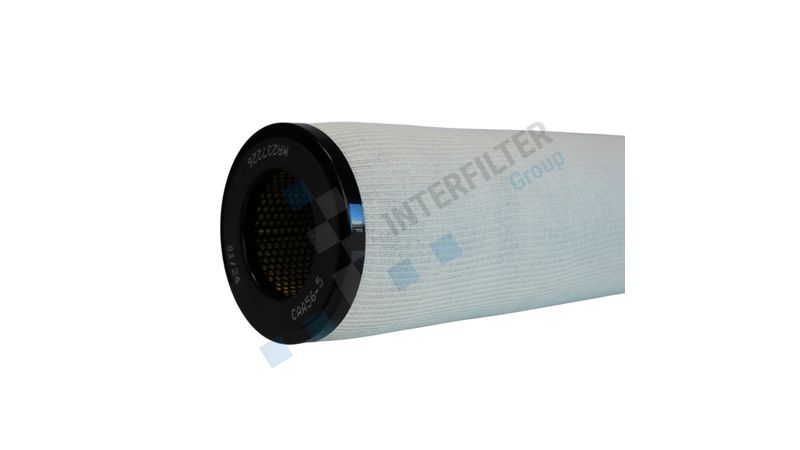

Coalescer filters

Join fine droplets in gas or liquid

Part description

What is a coalescer filter element?

A coalescer filter is designed to capture fine droplets of a liquid (such as water) from a gas or liquid stream. These droplets are brought together (coalesced) into larger droplets that can then be more easily separated. The coalescer element consists of various layers of specialized filter materials that capture fine water droplets from an oil or gas stream and bring them together into larger droplets.

Types of coalescer elements

Coalescing is often done within the oil and gas industry to separate water from oil. Interfilter offers coalescer elements made up of a multi-layered medium, medium with an integral pre-filter layer, or without an integral pre-filter layer where the filter medium consists of glass fiber. In addition, our CAA series has been tested and certified according to the 5th edition of API 1581.

Where are coalescer filters applied?

- Fuel filtration (for example aircraft fuel to remove water from fuel).

- Gas filtration to remove water or oil from natural gas.

- Removing water from oily liquids or chemicals.

- Industry: chemicals, resins, solvents, hydraulics, oils, and lubricants.

- Petroleum refinery: hydrocarbon stocks, fuels, crude, condensates, and distillates.

- Pipelines and petroleum terminals: diesel, gas oil, kerosene, LNG, and LPG.

- Electricity production: turbine lubricating oil and hydraulic oil.

- Pulp and paper: lubricating and hydraulic oil.

- Electricity transfer: transformer oils.

Specifications of coalescer elements

- Filtration: 0.3 to 5 microns, depending on the application.

- Nominal lengths: 11.25 to 57 inches

- Materials: glass fiber, polyester, polypropylene

- Element with multi-layered medium available for higher efficiency.

- Elements available with or without integral pre-filter layer.

- Recommended max. operating temperature: 115 °C

- Maximum flow rate: can vary from 10 liters per minute to thousands of liters per minute, depending on the size of the element.

- pH range from 5 to 9

- Core and support basket: steel (galvanized or tinned)

- End caps: steel (galvanized or tinned)

- Gasket: buna-n

- Flow direction: from inside to outside

- Certified according to the 5th edition of API 1581, category "C" type "S"

Free advice on coalescer filters

For more information, you can read our specific datasheet of the coalescer filter or contact one of our employees. Our employees are happy to provide you with tailored advice for your process.

More information about the type of process filter can be found on this page.

EN

EN

NL

NL PL

PL