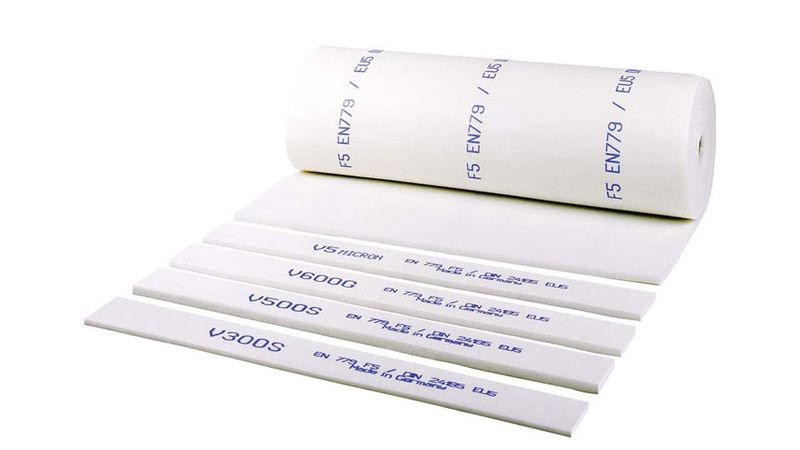

Ceiling filter cloth

Class ISO ePM10 50% (M5-M6)

Part description

Ceiling Filters

Applications of Ceiling Filters

- Paint shops

- Coating plants

- Printing houses

Benefits of Ceiling Filter Media

- Available on rolls or custom-cut

- Low pressure drop across the filter

- Fully combustible

Features of Ceiling Filters

- Filter class according to ISO 16890

- Medium: Synthetic

- Max. temperature: 100°C

- Max. relative humidity: 100%

Key Functions of the Ceiling Filter

Ceiling filters are commonly used in paint shops and coating lines. They serve several important functions:

Air Distribution

Ceiling filters ensure even distribution of clean air in the spray booth. This helps create a consistent airflow over the entire surface of the workpiece, promoting even paint application and reducing the chance of paint mist.

Protection of Lighting

In many spray booths, lighting fixtures are installed in the ceiling. Ceiling filters act as a protective barrier for these fixtures, shielding them from paint mist and dust particles that can be released during the spraying process. This extends the life of the lighting and minimizes the need for frequent cleaning.

Improvement of Air Quality

By filtering impurities from the air, ceiling filters help maintain a clean working environment in the spray booth. This is crucial for preserving the quality of the paintwork and for the health and safety of employees.

Extending the Lifespan of Other Filters

Ceiling filters serve as pre-filters for other filtration systems in the spray booth, such as the primary and secondary filters. They capture larger particles and dust before these reach the more specialized filters, thereby extending the lifespan of these filters and reducing maintenance costs.

For more information, you can download the data sheet or contact one of our employees.

EN

EN

NL

NL PL

PL